5 Industrial Scraps That Are Worth More Than You Think

You might be surprised to know that some of the most valuable scraps in industrial settings are items that don’t look like scrap at all. Often, these “undercover” materials contain rare metals, specialty coatings, or high-performance alloys that hold unanticipated value once recovered.

What sets these scraps apart is not just the base metal, but the hidden elements within them. A lot of these scraps come from highly specialized industries, which means they contain rare materials that are costly and difficult to mine. Recycling them keeps those resources in circulation and reduces reliance on raw extraction.

5 Surprising Sources of Valuable Industrial Scraps

Knowing what to look for can turn a disposal problem into a new revenue stream.

Here are five types of industrial scraps that can hold far more value than expected.

1. Titanium Anodes

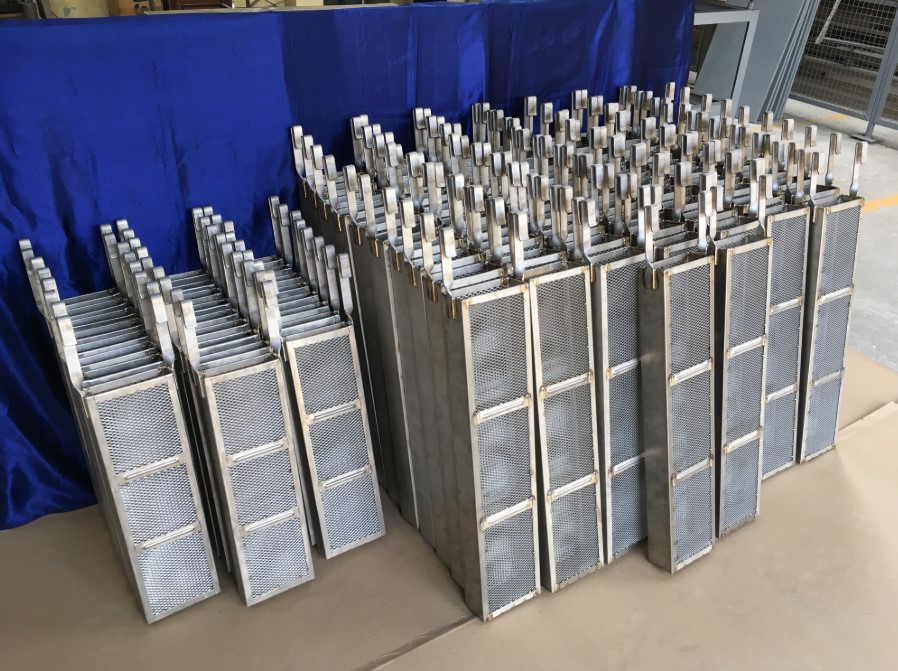

Titanium anodes are widely used in electroplating facilities, wastewater treatment plants, and chlorine production systems.

On the surface, a spent anode might look like a dark, worn piece of metal ready for disposal.

In reality, it often contains coatings made from rare metals like:

- Iridium

- Ruthenium

- Platinum-group oxides

These coatings are applied to improve conductivity, corrosion resistance, and catalytic activity.

Over time, however, they degrade, and the anode isn’t as efficient. While a used titanium anode may seem useless for its original application, its coating is actually a valuable resource.

Titanium anode recycling specialists can strip the surface layer, recover the rare metals, and return them to industrial use.

The titanium base itself has meaningful value, too. Unlike many metals that corrode or weaken after use, titanium often remains intact. This allows recyclers to remelt it into new ingots or even refurbish the base for continued industrial use. That means both the core and the coating can be reclaimed.

2. Tungsten Carbide Tools

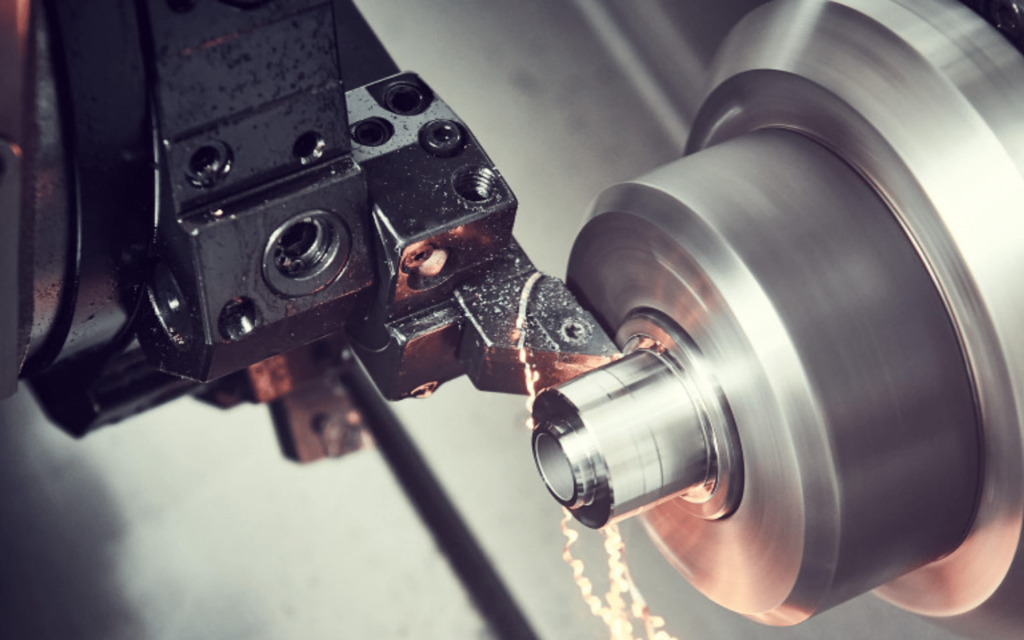

Tungsten carbide is known for its extreme hardness and durability. That’s why it shows up in machine shops, mining operations, and construction sites in the form of drill bits, cutting inserts, and wear parts.

These tools are often pushed to the limit and eventually wear down, leaving behind a pile of what looks like dull, broken pieces.

The surprising fact is, worn carbide tools can be worth a lot of money. Tungsten is a strategic metal used not only in tooling but also in aerospace, defense, and electronics.

Recycling companies process the scrap by crushing or milling it into powder. Then, this powder can be refined into fresh tungsten carbide for new tools.

Because tungsten supplies are concentrated in a small number of countries, recycled material plays an important role in maintaining availability. Manufacturers often prefer recycled tungsten because it reduces costs while maintaining performance standards.

Even small amounts of tungsten carbide scrap can yield impressive returns, so it’s become a top priority for industrial recycling.

Businesses that generate this type of scrap can improve their bottom line by working with a recycler that pays fairly for used carbide. It transforms what looks like worn-out hardware into a steady stream of value.

3. Molybdenum Turnings and Chips

Molybdenum is another high-value metal you might be overlooking. It’s used in everything from oil and gas pipelines to stainless steel manufacturing, where it improves strength, hardness, and corrosion resistance.

When parts are machined, the leftover turnings and chips may appear to be little more than piles of curly shavings.

Those small scraps, however, carry real value. Molybdenum doesn’t lose its properties during recycling. This way, even the smallest chips can be processed and reused in alloy production.

Recyclers collect, sort, and refine the turnings to extract the molybdenum content. The reclaimed metal can then be reintroduced into steelmaking or used in specialty alloys that serve demanding industries.

For companies that do large-scale machining, the volume of molybdenum chips produced can be substantial. Throwing them away is equivalent to throwing away money.

With proper collection, storage, and recycling, these shavings can offset material costs and contribute to more sustainable operations.

4. Infrared Optics and Germanium Scrap

Germanium is a lesser-known element with unique properties that make it valuable in the optics industry. It is a key component in infrared lenses used for thermal imaging cameras, security systems, and night-vision equipment.

Germanium is also used in:

- Fiber optics

- Solar cells

- Semiconductor applications

When infrared optics become outdated, cracked, or worn, they are far from worthless. The germanium content in the glass or crystal can be carefully recovered through recycling. Specialized processors extract the element and refine it for reuse in new lenses or other high-tech applications.

Germanium is not mined in large volumes compared to other metals, which keeps supply tight. As a reliable secondary source, recycling germanium supports industries where precision and performance matter.

For defense contractors, renewable energy companies, and electronics manufacturers, having recycled germanium available is a practical way to meet demand.

Old thermal camera lenses or security optics might appear useless to the untrained eye, but in reality, they’re a valuable feedstock for recovering one of the most specialized materials used in modern technology.

5. Nickel Alloys from Aerospace Applications

Few industries demand as much from their materials as aerospace. Jet engines, turbines, and critical components are built from nickel-based superalloys that can withstand extreme heat and pressure.

These alloys are expensive to produce and rely on elements like nickel, cobalt, and chromium that are increasingly costly to source.

When aerospace parts wear out, they are often retired from service for safety reasons. Yet the alloys themselves remain highly valuable. Recyclers with the right expertise can cut, melt, and separate these alloys to extract their nickel and cobalt content. The refined metals are then fed back into alloy production, reducing reliance on newly mined supply.

The process is not simple, but the returns are substantial. Nickel and cobalt are essential for aerospace, energy, and battery production, which keeps demand high.

For aerospace companies, recycling provides both financial benefits and a way to align with sustainability goals. Instead of treating old engine parts as waste, they become a source of premium materials for the next generation of technology.

Is There Hidden Value in Your Industrial Scrap?

Industrial scraps should never be underestimated. From titanium anodes coated with rare metals to tungsten carbide tools, molybdenum shavings, germanium optics, and nickel alloys, what looks like waste often holds hidden value.

The trick lies in working with recycling partners that understand how to identify and process these materials. Specialized knowledge ensures rare metals are recovered safely and efficiently, while businesses receive fair returns on their scrap.

For companies producing industrial waste streams, taking a closer look at what’s being discarded can uncover a hidden asset. Each type of scrap tells a different story, but all of them share the potential to be turned into value rather than loss. Recognizing these opportunities benefits both the bottom line and the broader effort to conserve resources.

Scrap recycling is no longer just about disposal. Take advantage of its value and uncover the worth of materials that still have much to offer and put them back into productive use.